Name: Jack

Tel: +86-513-55880140

Fax: 86-513-65860718

Mobile: WhatsApp:86-15862708570

E-mail: info@globalcarbonbrush.com

Add: No.503,14 Buliding, Guoliyuan, Chongchuan District, Nantong city, Jiangsu Province, China

Skype: carbonspjack

MSN: carbonspjack@hotmail.com

Assessment of Performance of Carbon Brushes

Commutator Appearance

In addition to the physical appearance of the surface of the commutator, the skin or patina is of equal importance for the good running of the carbon brushes. Each carbon brush builds a characteristic patina which is affected by operating and ambient conditions. The patina consists mainly of copper oxides, graphite deposits and adsorbed water, and its appearance is of importance when assessing the most suitable brush grade. The following pictures show typical appearances of commutation surfaces.

The pictures are not of an international standard specification but are used by carbon brush manufacturers and users of brushers as a guide to assist in judging the operation of carbon brushes.

Normal Skin or Patina Formation

|

P2, P4 and P6 are examples of normal skin or patina formation. When a machine runs well, the patina or skin on a commutator will be even, slightly shiny and coppery brown to black in colour. There may be appearance of greyish, blueish and reddish hues. but of importance is the evenness of the skin formation and not its colour. |

Appearances of Badly Formed Patina or Skin

|

P12 • Appearance: Streaky patina having some wide and narrow tracks of different colour. No commutator wear. Causes: High humidity, oil vapour, aggressive gases in the atmosphere, low electrical load on the brushes. |

|

P14 • Appearance: Torn patina, general appearance as in P12, but with narrower tracks and commutator wear. Causes: As in P12, but the condi-tions have been maintained for a longer period causing commu-tator damage. |

|

P16 • Appearance: Smutty patina, uneven skin having patchy colours and random spots. Causes: Uneven commutator or unclean operating conditions. |

|

P22 • Appearance: Patina with dark areas, regular or irregular patches covering one or more commutator segments. Causes: Out of round commutator, vibrations of the motor caused by badly adjusted shaft or damaged bearings. |

|

P24 • Appearance: Dark patchy patina having definite edges as in Tl2 and T14. Causes: Raised segment or group of segments causing the brush to bounce. |

|

P26 • Appearance: Commutator segments having patches in the middle or at the edges. Causes: Often due to faulty grinding of the commutator. |

|

P42 • Appearance: Alternating light and dark bar markings . Causes: Uneven current distribution over two parallel windings caused by double windings crossing in the same slot. |

|

P46 • Appearance: Mat patches in double pole pitches . Causes: Usually by faulty soldering of the risers or segment connections. |

Bar Burning

|

|

|

B2, B6, B8. Appearance: Bar edge burning or burning in the middle of bar. Causes: Sparking caused by commutation problems. |

|

B10 • Appearance: Perforated patina, light, dense or distributed build-up spots. Causes: Patina destruction caused by too large electrical resistance. |

||

Bar Marking

|

T10 • Appearance: Dark patches at edge of bars in direction of rotation. Causes: Frequently caused by long periods with the motor being stationary without power or short stationary periods under load. |

|

T12 • Appearance: Burning of a trailing edge and the next leading edge of a bar. Causes: Caused by protruding segment as in L2. |

|

T14 • Appearance: Dark markings. Causes: Sign of a low segment, could also be caused by a flat spot on the commutator (see L4). |

|

T16 • Appearance: Clearly defined dark markings together with segment edges burnt. Causes: Raised mica (see L6). |

|

T18 • Appearance: Dark markings. Causes: Badly undercut segment edges (see L8). |

|

L2 • Protruding segment L4 • Low segment L6 • Raised mica L8 • Ridge on the segment edge Causes: Faulty commutator segments L10 • Copper drag Causes: Bumps or vibrations from various causes |

Appearance of the Brush Sliding Face

The following pictures show typical brush-sliding faces. For easy identification we suggest you use the symbols S1, S3 etc.

S1, S3 and S5 are satisfactory sliding faces, indicating that there are no mechanical or electrical problems. Depending on the carbon material the sliding surface appears dense or porous, and shiny dull or matt.

If there is dust in the circulating air fine hairlining may occur as shown in S5.

|

S1 • Dense, shining sliding face | Problem free operation |

|

S3 • Slight porous sliding face | Problem free operation |

|

S5 • Fine hairlining | Normal operation, slight dust influence |

|

S7 • Hairlining | Causes: Underloaded, influence of dust, oil or grease. |

|

S9 • Tracking with hairlining and groves | Causes: Like S7, but stronger. |

|

S11 • Ghostmarks, difficult commutation | Causes: Commutation problems,e.g. false or incorrect position of the neutral zone or interpole. |

|

S13 • Burning edge of the leaving or trailing edge |

Causes: Difficult commutation, heavy sparking, interruption of contact due to out of round of commutator or insufficient brush holder spring pressure. |

|

S15 • Eroded brush face | Causes: Electrical overload, interruption of contact. |

|

S17 • Lamination of sliding face | Causes: Burned segments of the sliding face caused by a winding fault giving voltage surge during commutation. |

|

S19 • Double facing here for a twin brush | Causes: Tilting of the brush in dual direction machine. |

|

S21 • Copper nests | Causes: Pick up of copper particles, often following copper drag. |

|

S23 • Broken edges | Causes: High raised lamination, commutator seriously out of round, brush chatter. |

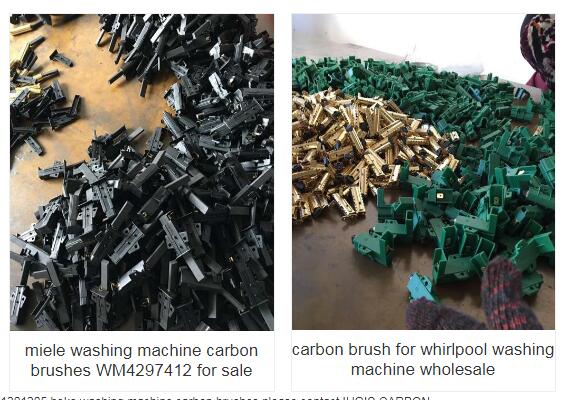

Carbon Brush For Power Tools

Carbon Brush For Power Tools